Essential Tips for Working with Poplar LVL Bed Strips

Release Time:

2025-06-09

Discover crucial considerations when using Poplar LVL Bed Strips in your woodworking projects.

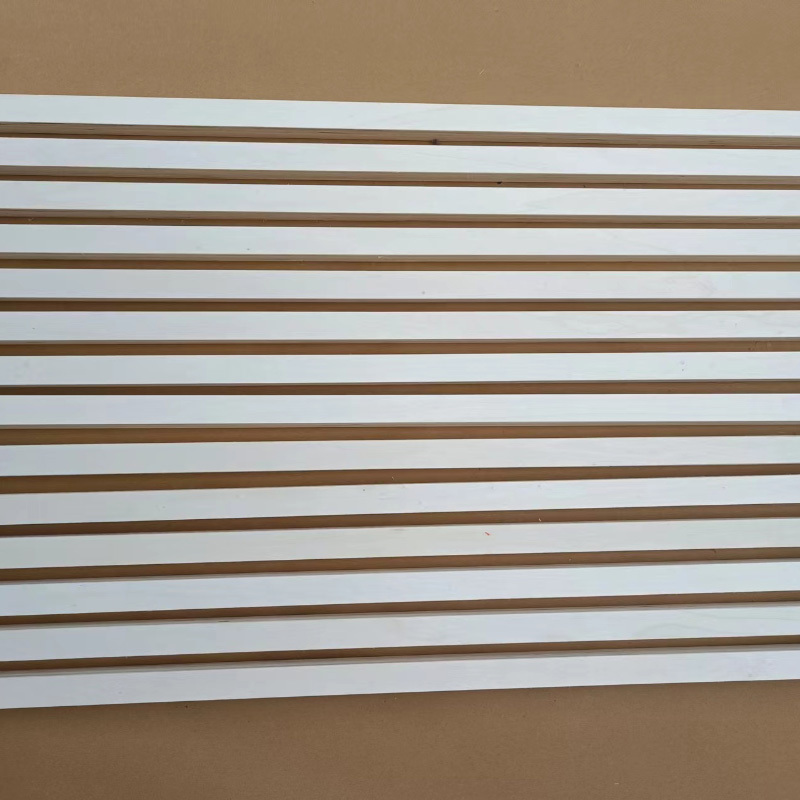

Introduction to Poplar LVL Bed Strips

Hey there, woodworking enthusiasts! If you’re diving into the world of bed frames or other furniture, you might have heard the buzz about Poplar LVL Bed Strip. These laminated veneer lumber (LVL) options are all the rage for their strength and versatility. But hold your horses! Before you start cutting and assembling, let’s chat about some important considerations.

What is a Poplar LVL Bed Strip?

Simply put, a Poplar LVL Bed Strip is a manufactured wood product made from layers of veneer glued together. It’s not just any wood; poplar offers a light color and a smooth finish, making it a favorite among builders. Plus, it’s immensely strong, which is a huge plus for any bed frame!

Why Choose Poplar LVL?

Let’s break it down! Why should you consider using a Poplar LVL Bed Strip? Here are a few reasons:

- Strength: These strips can bear loads without bending or warping.

- Stability: LVL is less prone to cracking or splitting compared to solid wood.

- Environmentally Friendly: Made from renewable resources, poplar LVL is a sustainable choice.

Key Considerations When Using Poplar LVL Bed Strips

Now, let’s get to the meat of the matter! Here are some easy-to-follow tips to ensure your project goes off without a hitch:

1. Measuring Twice, Cutting Once

Ah, the age-old saying! Always double-check your measurements. This is especially crucial with Poplar LVL Bed Strips as they come in various dimensions. A little miscalculation can lead to a lot of headaches later!

2. Know Your Tools

Make sure you have the right tools for the job. Circular saws or table saws are great for cutting Poplar LVL Bed Strips. Just be mindful of the blade type—using a fine-toothed blade can help prevent splintering.

3. Plan for Moisture

Poplar is generally resistant to moisture, but it’s still a good idea to keep your workspace dry and protect your strips. Moisture can lead to warping over time, which is a big no-no!

4. Sanding is Key

Once you’ve cut your pieces, give them a good sanding. This not only smooths the edges but also helps your finish adhere better. Trust me, you’ll be glad you took the time!

5. Finishing Touches

Speaking of finishes, remember that poplar can absorb stain unevenly. If you’re planning to stain your Poplar LVL Bed Strips, consider using a pre-stain wood conditioner. It’ll help you achieve that smooth, even look you’re aiming for.

Common Mistakes to Avoid

Let’s face it—nobody wants to make rookie mistakes. Here are a couple of common pitfalls to steer clear of:

- Ignoring Grain Direction: Always pay attention to the grain when cutting. It can affect the strength and appearance of your final product.

- Underestimating Weight: While poplar LVL is strong, don’t overload your bed frame. Always adhere to the weight limits!

Conclusion: Get Crafting!

So there you have it! With these tips in your back pocket, you’re all set to start your next project with Poplar LVL Bed Strips. Remember, preparation is key, and with the right approach, your woodworking journey will be smooth sailing. Happy building!

TAG:

Message

We will contact you within one working day. Please pay attention to your email.

Quick Link

Contact Us

Contact: Manager Wang

No.9 Village, Anling Town, Jing County, Hengshui City, Hebei Province