Historical Evolution of Bed Slats: The Rise of Durable LVL Materials

Release Time:

2025-06-09

Historical Evolution of Bed Slats: The Rise of Durable LVL Materials The world of bedding has undergone a significant transformation over the years, particularly in the realm of bed slats. Originally crafted from solid wood, bed slats have evolved into complex structures incorporating engineered materials like Laminated Veneer Lumber (LVL). This article delves into the historical development of be

Historical Evolution of Bed Slats: The Rise of Durable LVL Materials

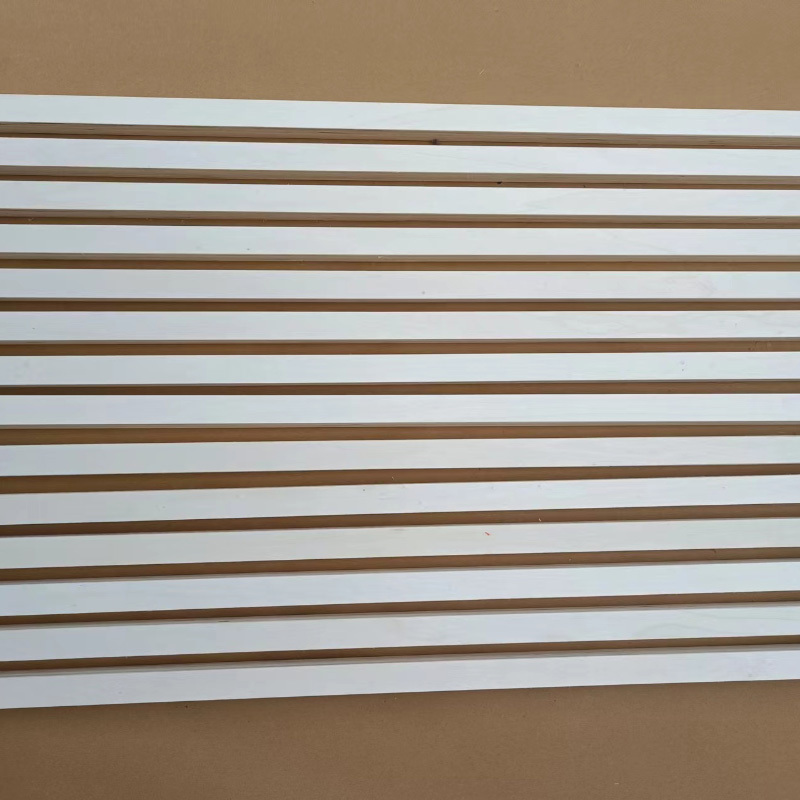

The world of bedding has undergone a significant transformation over the years, particularly in the realm of bed slats. Originally crafted from solid wood, bed slats have evolved into complex structures incorporating engineered materials like Laminated Veneer Lumber (LVL). This article delves into the historical development of bed slats, highlighting the rise of LVL and its lasting impact on the bedding industry.

A Brief History of Bed Slats

Bed slats, integral to the support system of beds, have evolved considerably since their inception. Initially, slats were made from solid hardwood, chosen for their strength and availability. As the demand for furniture increased, so too did the need for innovative materials that could withstand the test of time.

The Early Days: Solid Wood Slats

In the past, bed slats were primarily constructed from planks of hardwood, such as oak and maple. These materials provided adequate support for mattresses but often came with drawbacks, including warping and splitting over time. Despite these issues, solid wood slats were the standard for centuries, valued for their natural aesthetics and durability.

The Limitations of Traditional Materials

Solid wood slats, while popular, presented several challenges. As wooden slats aged, they could suffer from warping due to changes in humidity and temperature. Furthermore, the weight of solid wood could make bed frames cumbersome and less flexible. Consequently, the need for a more efficient and reliable material became evident to manufacturers and consumers alike.

The Advent of Engineered Wood Products

As manufacturers sought alternatives to traditional wood, engineered wood products began to emerge. These materials, designed to enhance strength and stability, paved the way for innovations in bed slat technology.

Introduction of Engineered Wood: Plywood and Particleboard

Plywood and particleboard marked significant advancements in bed slat construction. Plywood, made from layers of thin wood veneer glued together, offered greater resistance to warping. Meanwhile, particleboard, composed of wood chips and resin, provided a cost-effective solution that maintained decent strength. Despite their advantages, these materials still fell short in terms of overall durability compared to solid wood.

The Rise of Laminated Veneer Lumber (LVL)

The most groundbreaking development in bed slat technology came with the introduction of Laminated Veneer Lumber (LVL). This engineered wood product is made by bonding together thin layers of wood veneers with adhesives under heat and pressure, resulting in a material that boasts exceptional strength and stability. LVL has quickly become a preferred choice in the bedding industry, offering numerous benefits over traditional materials.

Why LVL is Revolutionizing Bed Slats

LVL materials have transformed the way bed slats are designed and manufactured. Understanding the advantages of LVL helps illustrate why it has gained popularity in modern bedding solutions.

Enhanced Strength and Stability

One of the most notable benefits of LVL is its superior strength-to-weight ratio. Unlike traditional wood, which can warp or crack, LVL maintains its structural integrity over time. This stability ensures that bed slats can support mattresses effectively without sagging or bending, providing an improved sleeping experience.

Resistance to Environmental Factors

LVL is engineered to resist environmental factors that often affect solid wood. This material is less susceptible to changes in humidity and temperature, making it an ideal choice for various climates. As a result, beds constructed with LVL slats tend to last longer and require less maintenance than those made with solid wood or other engineered products.

Cost-Effectiveness

Given the durability and strength of LVL, it often proves to be a more cost-effective solution for manufacturers and consumers. While the initial investment may be slightly higher than traditional materials, the long-term benefits of reduced maintenance and increased lifespan make LVL a smart choice for bed slat construction.

Design Flexibility

LVL's versatility allows for unique design possibilities that weren't feasible with solid wood. Manufacturers can create custom bed slat configurations and designs, enhancing both aesthetic appeal and functionality. This flexibility is particularly valuable in modern furniture design, where consumers seek personalized solutions that fit their individual preferences.

The Role of Technology in LVL Production

The production of LVL involves advanced technology that enhances its quality and performance. Understanding this process sheds light on why LVL is rapidly becoming the industry standard for bed slats.

Precision Manufacturing Techniques

Modern manufacturing techniques enable manufacturers to produce LVL with exceptional accuracy. Computer-controlled machines ensure consistent thickness and quality, reducing the likelihood of defects and ensuring that each slat meets stringent quality standards. This precision translates into enhanced performance for consumers.

Adhesive Innovations

Advancements in adhesive technology have also played a critical role in LVL production. High-quality adhesives are vital for ensuring that the veneers bond correctly, contributing to the overall strength and durability of the finished product. By using superior adhesives, manufacturers can produce LVL that is both strong and environmentally friendly.

Consumer Insights: The Preference for LVL Bed Slats

As awareness of the benefits of LVL continues to grow, consumer preferences are shifting. The following factors contribute to the increasing demand for LVL bed slats.

Focus on Sustainability

Modern consumers are increasingly concerned about sustainability and environmental impact. LVL is often produced using sustainably sourced wood, making it an eco-friendly choice in the bedding industry. This commitment to sustainability resonates with many consumers, influencing their purchasing decisions.

Health and Wellness Considerations

Quality sleep is paramount for health and wellness. By offering enhanced support and stability, beds with LVL slats contribute to better sleep quality. As more consumers become aware of the importance of a good night's sleep, they are more likely to invest in quality bedding solutions that prioritize comfort and support.

FAQs About Bed Slats and LVL Materials

1. What are bed slats made from?

Bed slats can be made from various materials, including solid wood, plywood, particleboard, and engineered wood products like LVL.

2. Why are LVL slats preferred over traditional wood slats?

LVL slats offer enhanced strength, resistance to environmental factors, and durability, making them a superior choice compared to traditional solid wood slats.

3. Do LVL slats require maintenance?

LVL slats require minimal maintenance compared to solid wood slats, as they are less susceptible to warping and damage from humidity and temperature changes.

4. How do LVL slats affect the overall comfort of a bed?

LVL slats provide improved support and stability for mattresses, contributing to a better sleeping experience and enhanced comfort.

5. Are LVL materials environmentally friendly?

Yes, LVL materials are often produced using sustainably sourced wood, making them an eco-friendly choice in the bedding industry.

The Future of Bed Slats in the Bedding Industry

The transition from traditional wood slats to LVL represents a significant shift in the bedding industry. As innovations continue to unfold, it is likely that LVL will remain at the forefront of bed slat technology. Manufacturers are increasingly recognizing the value of engineered materials, leading to further advancements in design and functionality.

Emerging Trends in Bed Design

With the rise of LVL, we can expect to see new trends in bed design emerge. The combination of aesthetic appeal and functionality will drive the creation of unique bed frames that cater to a wide range of consumer preferences. From minimalist designs to elaborate statement pieces, LVL will play a crucial role in shaping the future of bedding.

Technology-Driven Innovations

Technological advancements in materials science and manufacturing processes will continue to enhance the performance of LVL materials. As manufacturers explore new ways to improve the sustainability and efficiency of production, we can anticipate even greater innovations in bed slat technology.

Conclusion

The evolution of bed slats from traditional solid wood to modern LVL materials reflects broader trends in innovation and consumer preferences in the bedding industry. LVL offers unparalleled strength, stability, and sustainability, making it the material of choice for contemporary bed slat construction. As we look to the future, it is clear that LVL will play a pivotal role in enhancing both the functionality and design of beds, ultimately contributing to better sleep and improved quality of life for consumers.

TAG:

Previous

Previous:

Message

We will contact you within one working day. Please pay attention to your email.

Quick Link

Contact Us

Contact: Manager Wang

No.9 Village, Anling Town, Jing County, Hengshui City, Hebei Province